The racking columns arrived in packs — each roughly five tons in weight and eight metres long. My forklift looked tiny beside them, more like a toy than a machine. I stood there, hands on hips, thinking, How on earth am I going to unload these monsters?

You might ask, “Didn’t you expect them to be that heavy? Steel is steel, after all.”

Well — yes, I did. And I thought I was ready.

I really had done my homework.

- I hired an unloading ramp so the forklift could drive straight into the container.

- I bought a 3.5-ton forklift, just as the supplier advised.

- I prepared eight rollers — solid sections of tree trunks — to help roll the heavy packs inside the warehouse.

- I bought ten heavy-duty straps, each rated for five tons, in case something broke loose during transit.

It looked like the perfect plan.

In reality, it was chaos waiting to happen.

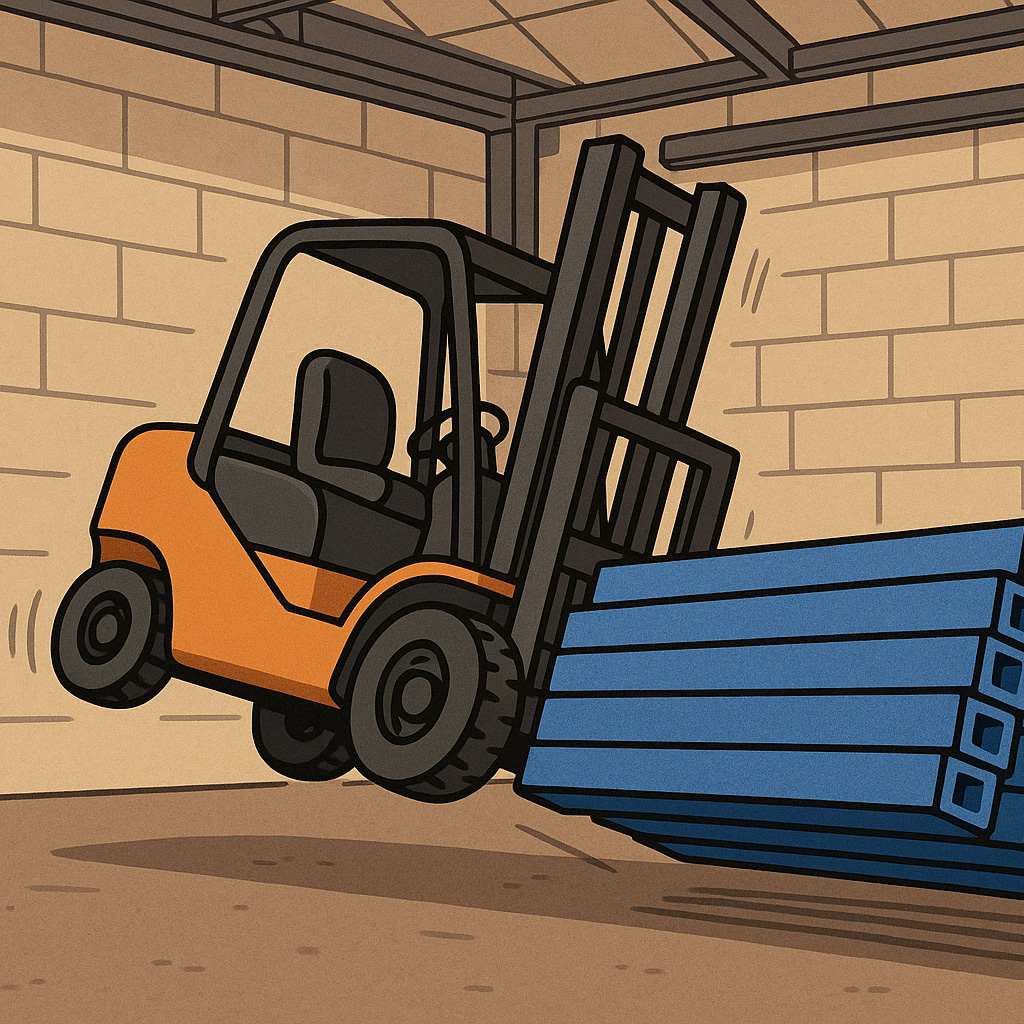

When we tried lifting the first pack, the forklift didn’t move it an inch. Instead, the back wheels lifted off the ground, and the whole machine tilted forward like a clumsy gymnast mid-fall.

That’s when the straps saved the day. We decided to split each pack in two, just light enough for the forklift. But that alone wasn’t enough — we still had to line up the rollers underneath to support the far end. For a brief moment, it seemed to work: the forklift lifted one end, rolled backward slowly, while the other end slid smoothly along the rollers, inch by inch.

Until the far end reached the container edge.

Then came the next nightmare — a two-metre drop to the floor. Keep sliding, and the entire bundle would come crashing down like a guillotine.

Our first solution was to stack wooden pallets beneath as a landing platform. It lasted about three seconds before the rollers punched straight through.

Next, we tried using two forklifts — one dragging the pack from inside the container, the other lifting and nudging the far end outward. It kind of worked — for a while — until the pack leaned sideways, crushing several beams into twisted scrap metal. By the time we finally got that load onto the floor, a quarter of the racking was damaged, and we spent another hour sorting and restacking the usable pieces by hand.

Eventually, after endless trial and error, we stumbled upon a method that — while painfully slow — actually worked:

- Two stacks of pallets as middle supports.

- One forklift to lift the far end and side-shift it out, just five inches at a time.

- The second forklift to drag backward slowly, keeping the movement steady and even.

It wasn’t elegant, but it worked.

By the time we perfected this “technique,” one container driver had already refused to wait, declaring our method “unsafe.” To be fair, he wasn’t entirely wrong.

And yet, even that humiliation wasn’t the hardest blow. What came next didn’t challenge my body — it tested my faith in people.

Next Chapter: The Unreliable Managers?

free to follow my BSS journey — where every low seems to bring another blow.

Leave a Reply